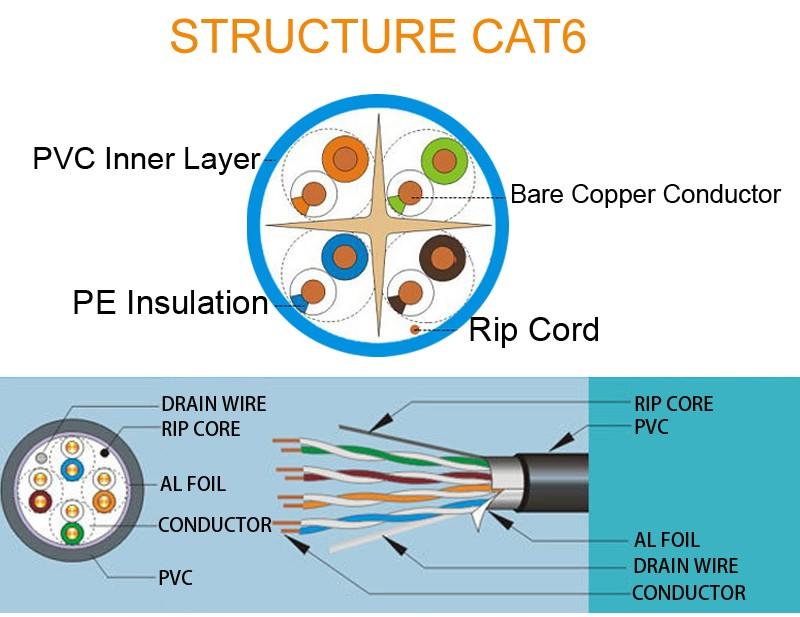

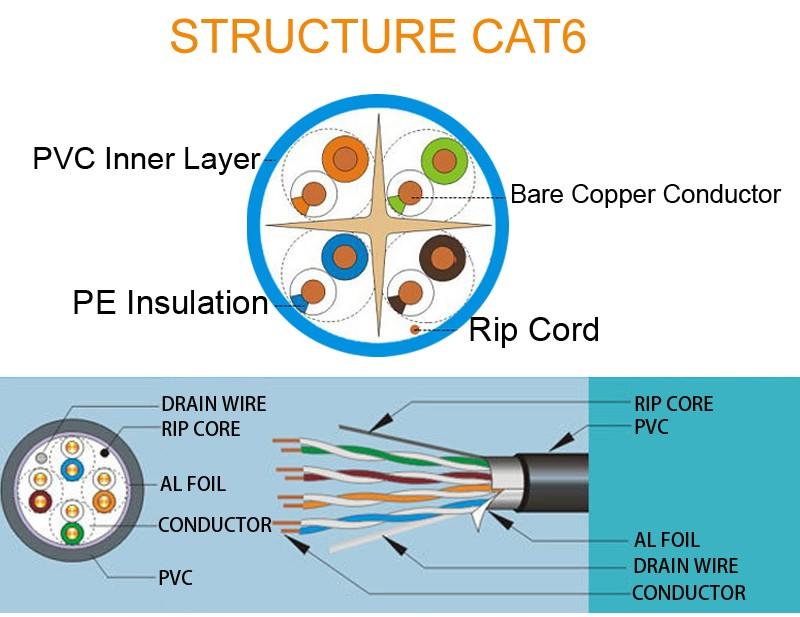

According to different kinds of cables, there are several different steps, such as Cross Filling, Metal Sheath Filling, Braided Wire Filling,Drain Wire Filling,Rid Cord Filling, Printing and so on, which are in order to produce the kind of cable needed finally.

Cross Filling (Separator filling). The twisted cables are heated to ensure that the cross can pass through the possible gaps and,finally, wrap the cable around the cross.

Metal sheath filling. Depending on the design of the cable, some cables require a protective metal sheath made of aluminum foil or steel. As a way to prevent the interference of static electricity to the signal in high voltage, aluminum foil has the functions of shielding, anti-radiation, anti-static and so on. Metal is designed to protect buried cables under the ground from damage by rats or other animals such voles.

Braided Wire Filling.

Now, due to the more interference of the signal and the design of different network cables, a layer of Braided Shield will be added in the network cable, which plays the role in preventing the interference caused by static electricity to the signal, with shielding, anti-radiation, anti-static effect.

Drain Wire Filling. Due to the damage caused by high voltage to the cable, some network cables will be designed with a drain wire, to discharge the induced or interference current as soon as possible, or to make the electric potential of the entire shield as equal as possible. Generally speaking, braided shielding is not needed, but separate braided shielding, because its cross-sectional area is very small, if there is no drain wire, the electric potential on the whole cable length may not be equal, which will produce interference current.

According to different designs, without braided shield, the aluminum foil is wrapped, the drain wire is placed into the aluminum foil, and the wire is dragged into when the wire is cabled, and the drain wire is in contact with the aluminum surface of the aluminum foil (aluminum facing inward).

In the case of braiding, the drain wire is placed onto the aluminum foil with the braided shield, and the aluminum surface faces outward.

Rid Cord Filling. High-quality network cables such as CAT6A,CAT7 CAT7A CAT8, generally there are a fiber called Rid Cord, which is not helpful to signal transmission at all. It can be used to peel the wire quickly when workers pull the wire skin without damaging the twisted pair.

Outer Cable Jacketing.

Then there is the outer cable sheath jacketing. According to different needs, the outer sheath generally has PE,PVC,LSZH and so on.

Indoor LAN/Ethernet cable is divided into two layers of skin, the inner skin refers to the plastic skin wrapped in copper wire with PE material, PE material is non-toxic, easy to color, good chemical stability, cold resistance, radiation resistance, good electrical insulation.Polyethylene (PE) is insoluble in any known solvent at room temperature, and resists to dilute sulfuric acid, dilute nitric acid and other acids of any concentration, as well as various concentrations of alkali and salt solutions. PE is UV resistant and PE can protect cables underground or when utility poles are in use in exposed sunlight.

The outer skin refers to the mesh epidermis we see, which is made of PVC. Generally, the new material or secondary material will be used according to the quality of the cables. The pvc chemical stability of the new material is good, and it is resistant to acid, alkali and some chemicals. It is moisture-resistant, aging-resistant and non-flammable (flame retardant). When it is used, the temperature should not exceed 60 ℃, and it will harden at low temperature. Sometimes it will be introduced that we use a new material of 75 degrees. In fact, 75 degrees does not refer to the temperature, but refers to the softness and hardness of PVC.

Cooling and Printing.

The final process is that after the jacketing, the cable will pass through the water tank where the temperature is controlled by the main controller and cool the sheath. When the cable is dry and the outer layer of the sheath is slightly hot, you can use the ink-jet printer to print fonts or marks on it.